We boost efficiency

For a more sustainable world, resources must be used efficiently. With lightweight design using specialist composites, reducing friction with advanced lubricants, tripological plastics and major components for Green Tires, Evonik offers a wide product spectrum to reduce CO2 . Our customized products raise standard plastics or rubbers to high-performing materials or enable in a circular economy the transformation of used polymers into new applications. We consider every step in a material’s life.

Processing & Assembling

DYNACOLL® based reactive hotmelts are well known for their versatile adhesion properties and very high temperature resistance.

For pre-coated automotive parts the coil coating DYNAPOL® offers very good adhesion to aluminum, steel and galvanized steel.

The short chained polybutadien POLYVEST® is a reactive plasticizer for adhesives, sealants and accustical damping in assembling the body in white, even for oily surfaces.

The HTPB (Hydroxyl-terminated polybutadiene) , which is being marketed under the trade name POLYVEST® HT by Evonik is well established as polymeric binder for high quality PU adhesives for automotive head lamps.

With epoxy-amine-systems based on VESTAMIN® the curing process of epoxy resins could be optimized for fast running production cycles and avoid the usage of styrene/anhydrid technology

VISIOMER® specialty methacrylates are used in reactive 2 component adhesive and sealant formulations.

Tires & Rubber

1,3 butadiene is used as a monomer for synthetic rubber like tires

Adhesion of rubber to fabric or steel cord for tires can be significantly improved with the so called RFS-system (Resorcinol Formaldehyde Silica). COFILL® 11 combines the resorcinol with the silica, so the handling is much safer but the excellent adhesion is the same.

In COUPSIL® products the silica is already pre-reacted with the silane. This makes the application of the Silica/Silane-system much simpler, because the complex silanization reaction in the mixer is obsolete.

POLYVEST® ST enables to improve the overall performance of silica-reinforced tire tread compounds in combination with sulfur silanes like Si 69® or Si 266®. Its application allows to significantly reducing the rolling resistance, which has been indicated by reduced PAYNE effect and tan delta at 60 °C in GREEN Tire and truck tire treads compounds.

Si 69® is a bifunctional, sulfur-containing organosilane for rubber applications like low rolling resitance Green Tires

TAC and TAICROS® are mainly used as crosslinking additives in peroxide or electron beam induced crosslinking to increase chemical resistance of rubber or thermal and chemical resistance in plastic materials

The TEGOSIL® thermal management portfolio improves the heat resistance and heat transfer performance of silicone rubber formulations, helping the automotive and transportation industries to meet new industry standards such as the latest EN 45545 standard.

The highly dispersible silica (HDS) ULTRASIL® enable the production of rubber compounds with low dust and easy mixing. It provide solutions for the compounder to improve the performance like e.g. wet traction and braking, wear and rolling resistance properties and in that way higher fuel efficiency and CO2 emission reductionof so called Green Tires.

VESTENAMER® improves compatibility, mixing, shaping, and product performance of rubber compounds. The world’s most versatile rubber additive can be used for manufacturing of tires, technical rubber goods or for efficient rubber recycling.

Lubricants

The superior wax crystallization control of VISCOPLEX® pour point depressants (PPDs) guarantees optimized oil flow behavior in cold climates, so vehicles and equipment can operate smoothly in adverse weather.

VISCOPLEX® viscosity index improvers (VIIs) feature polymers that contribute to higher viscosity at high temperatures and offer minimal viscosity contribution at lower temperatures. They are used to formulate multigrade engine oils, transmission fluids, hydraulic fluids, gear oils and other industrial lubricants.

Specialities

The MTBE (Methly-tert, butyl ether) based anti-knocking agent DRIVERON® helps to reduce emisions of vehivles, worldwide.

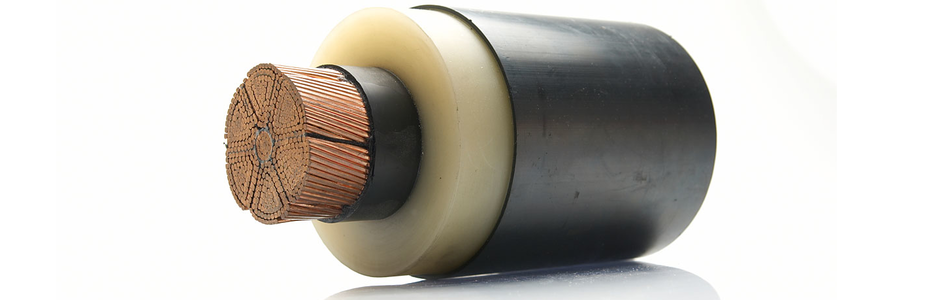

With Dynasylan® it is possible to crosslink mineral filled thermoplastic compounds like hologen free flame retardend cable insulations to increase the thermostability and safeness of the automotive wiring harness

The organic modified silioxanes of the TEGOMER® product family helps to improve the flowability and wetting of highly filled compounds, like e.g., polyamide compounds in under the hood applications, as well as the glossiness and scratch resistance of compounds, or high gloss PMMA or PC/ABS compounds used for auto interiors.